Types of devices

As a rule, device repair consists of changing the component unit. Why do you need to buy a new mechanism and replace the broken one with it? For example, it is impossible to inflate the cuff with air. This means that the pumping check valve in the bulb has broken. It is pointless to change only the valve; you need to replace the entire assembly, along with the tubes.

Electronic and semi-automatic machines are several times more expensive than a mechanical device. These types of devices do not have very frequent malfunctions. What often happens:

- malfunctions in the mechanism itself;

- absence or delay in displaying indicators;

Problems in displaying indicators

It is better to fix serious breakdowns at a service center, because a warranty card is issued for repairs, and until it expires, it is prohibited to carry out repairs on your own. You can change the bulb, cuff, and batteries yourself; the warranty card does not apply to them.

Why does it show arrhythmia (different results with repeated measurements)

When measurements differ, you need to check whether the actions are correct. A person can make mistakes when taking measurements. The most common reasons for different readings during measurements:

- incorrect position of the cuff;

- heart rhythm disturbance;

- insufficient battery life for measuring pressure;

- incorrect body position.

Correct installation of the cuff is important. If installed incorrectly, the degree of pressure on the arteries changes, which leads to different measurement results. This feature is typical for wrist tonometers. The narrow sleeve should be placed over the radial vein. If the cuff does not fit tightly, is displaced or rotated, the indicators will fluctuate.

Don't trust electronic devices. Electrotonometers do not take into account arrhythmia. Indicators may change with repeated measurements. To correct the situation, you need to replace the tonometer. It is better to order a device with an indicator that shows arrhythmia. The device will take several measurements sequentially and display the overall average value.

Another common reason is low battery charge. This is typical for tonometers that operate on AA batteries. Cheap devices do not have a charge indicator, which can be used to judge the degree of wear, so when the service life is exhausted, the tonometer does not display the pressure correctly.

If the body position is incorrect, the measurements will change and the tonometer will show different pressure. It is recommended to measure blood pressure while sitting. The arm with the cuff should be at heart level. The error when measuring while lying down is 10 points. If the hand is located above the level of the heart, the readings will be 7-10 units lower than the real ones.

Correct installation of the cuff is the key to obtaining correct readings

How to repair a tonometer correctly: features and recommendations?

If you decide to save time and money and repair the tonometer yourself, you must first find faults in the device. If a person uses it often, then identifying a broken part will not be difficult. If the problem is air leaking from the system, then it needs to be identified. Having found the place where the air is leaking, you simply need to replace this element with a new one. If after this the pressure measurement went well, then everything worked out.

How to repair a mechanical tonometer with your own hands?

What kind of breakdowns can a mechanical device have and how to fix them yourself:

- The cause of the breakdown is the pressure gauge needle falling out. There is no way to fix the problem yourself. It is recommended to buy a new pressure gauge and replace the broken one with it.

Pressure gauge in a mechanical tonometer

Valve sticking in bulb

You can buy the necessary part for a mechanical tonometer in an online store, order by phone, or in a medical equipment store.

Features of electronic equipment repair

Breakdowns and repair methods for electronic devices:

- When unrealistic indicators are displayed on the display, you must first replace the battery. If this does not help, you need to look for an air leak in the cuff, bulb and the pipe connecting them. Here, repairs are carried out depending on the circumstances: replacement with new parts or elimination of leaks.

A quick solution to the problem is to change the battery

Automatic devices are not so easy to disable. If the tonometer is not dropped, hit or shaken forcefully, it will last for many years. The electronics inside the camera are quite fragile and require delicate and careful handling.

Graphic blood pressure level indicator

It can be difficult for an elderly person to keep a few numbers in mind and remember what normal blood pressure should be. For such people, as well as for greater clarity, many tonometer models have a graphic indicator of the blood pressure level.

Graphic blood pressure level indicator

All manufacturers position the scale differently. For some brands it is located on the body, while for others it is on the display. Figure 3 shows a tonometer with a scale placed on the body. A slider on the screen is displayed next to the danger level. The position of the slider in the green zone means that the indicator is within the normal range; if the slider is in the red zone, you should consult a therapist or cardiologist.

Repairing a holey cuff

If the problem is bleeding air, then you need to find the location of the gap. When it is located directly on the cuff, it does not have to be replaced; it can be repaired. How to repair a leaky blood pressure cuff:

- If the hole is small and the cuff is strong and unworn, then you can seal it with a hot glue gun.

- You can glue a piece of rubber patch or other suitable material onto the gap with rubber cement.

- Take a strip of thick aluminum and bend it in half. Push the damaged area between them and clamp it with metal, help yourself with pliers. Cover this place with glue.

When air escapes at the factory soldering site, it can be vulcanized with a soldering iron at 180 degrees. It is important to remember that repairing a cuff is cheaper than replacing it, but it will not last too long after the intervention. Therefore, be prepared to replace this element.

Video 1

So, for the measurement process, 5 volts with a maximum current consumption of 260 mA was enough for the device. It is well known that the operating voltage of the motor should not be higher than 110% and lower than 90% of the rated one. That is, in this case, 5.5 volts is allowed. It is worth remembering that there is a spread in the output voltage of linear stabilizers, including in a larger direction, so that it is quite possible to find a “stub” at 5.5 V. The engine will run for 20 seconds at most, so that I don’t think it will have time to overheat. By the way, it would be appropriate to remember how long it has to buzz when its zealous owners are diligently “refining” a set of batteries that are already pretty weak. Have you decided? Now to the essence of what was planned:

First of all, the air supply tube is disconnected, the battery compartment cover is opened and two screws are unscrewed from the cylindrical recesses and the halves of the case are separated. Here are the internal contents. Now the main thing is not to rush and fuss.

We lift the liquid crystal display and move it to the back side, access to the power socket appears.

Using soldering, we are assembling a connection diagram for the stabilizer; nevertheless, I decided to set it to 6 volts.

We remove it from the installation site of the power socket, take it to the side and first unsolder the positive wire (red), in its place the positive wire coming from the input of the stabilizer, and connect the positive output wire to the previously soldered red wire.

We do the same with the negative wire (blue), which wire is positive and which negative is determined by checking the wire with the power plug inserted before soldering begins.

The socket is in place, the stabilizer with the radiator is secured with a self-tapping screw to the bottom of the case.

We return the display and the air duct tee to their place, we insert the power wires into the case, having previously wrapped the soldering points with tape.

The result of the work. From the available chargers for cell phones, I selected a suitable one (its modification consisted of replacing the plug) at the output (without load) it gives 8.5 V. However, now any power supply with an output voltage from 8.5 to 15 volts will do. The essence of interfering with the factory design is that there are any number of power supplies for 5, 8, 10, 12, 15 volts, but 6 volts are rare.

How to properly disassemble the AND tonometer?

Tonometer model AND UB 201

The AND UB 201 tonometer is a bracelet-type device for measuring blood pressure. Most often, the cuff fails with this model. To repair or replace it, it must be removed correctly. This is done in the following sequence:

- The batteries are removed from the camera.

- Remove the clips that secure the cuff (they are located on both sides of the body) by prying them off with a screwdriver.

- Pull the cuff towards you and release it from the tonometer body, to which it is attached with two more latches.

- The housing cover is attached with two bolts at the back; they need to be unscrewed with a screwdriver. Carefully open the cover and remove it.

- To completely disassemble the tonometer, you should press in the recesses at the top of the case with the same screwdriver, and it will easily fall apart.

Heart rate

The third digit located on the device display is the pulse. This figure is located in the bottom row under the pressure indicators.

Heart rate indicator

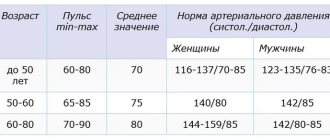

It is not difficult to understand what this or that number located on various models of tonometers for measuring pressure means. Heart rate depends on the age and gender of a person; on average, this indicator varies from 60 to 90 beats in 60 seconds. A rarer pulse may indicate bradycardia, a more frequent pulse may indicate tachycardia.

Stages of recovery

procedure for receiving equipment, performing diagnostics and troubleshooting

Carrying out diagnostics

- Free diagnostics of the device verbally or on site within 15 minutes.

- The device must be left for comprehensive diagnostics.

Price negotiation

- We agree on the cost and timing of repairing the device before starting work

- When there are no spare parts, more problems are identified - we coordinate

Recovery

- The device is being repaired at a service center.

- Device repairs

usually take up to 7 days, in difficult cases up to 25 days.

Issuance and verification

- The repaired device is checked and tested.

- A “Certificate of Work” is issued with a guarantee for the work performed

- of the device is possible .

Motion indicator

On some tonometer models there is a motion indicator on the display. As a rule, it depicts a human figure.

Movements while using the device can cause the device to display incorrect data, which in turn will lead to an error in diagnosis. The appearance of a motion icon on the device screen encourages the user to assume a state of rest and take the measurement again.

Free diagnostics

About the features of free diagnostics

To find out the cause of the malfunction, the approximate time frame for work to restore functionality and the cost of eliminating defects, you can simply send the device for diagnostics . To do this, simply bring (look up the address) ( get directions on Google or Yandex ) the faulty equipment for diagnostics at the service center

Why is diagnostics free ? Sometimes a specialist needs to disassemble the device in order to understand the complexity of the proposed work to restore the functionality of your tonometer . This is necessary to announce the cost of repairs and the timing of the work performed.

About urgent repairs at the service center

Urgent repair of the AED tonometer on site within 20-30 minutes is possible. If the entire process supposedly does not take more than 10 minutes, including disassembling and assembling the device. Urgent repairs are carried out at the discretion of the specialist, taking into account your request. The customer can wait until the end in the service center waiting area.

Why leave equipment in service?

Your AED is waiting for its turn , because we are diagnosing/repairing laptops of other customers.

A specialist needs time to assess the complexity of work to restore the functionality of equipment and to find faults at the modular or component level.

You also need to find serviceable spare parts in stock at the service center or check their availability with the supplier.

About receiving equipment at the service center

When accepted for diagnostics, at the Repair service center, a “ Device Acceptance Certificate ” is issued. Upon completion of the repair work, a “ Certificate of Completion ” is issued with a guarantee for the services performed.

If you decide to refuse to carry out repair work to restore the functionality of the device, then you need to familiarize yourself with the “ Regulations for refusing to carry out work ”

High pressure indicator

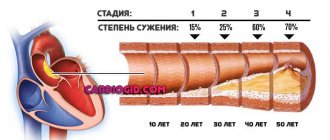

Deviation of blood pressure readings from the norm is a serious signal that may indicate heart disease. And the treatment of such diseases must be approached without delay. That is why on the displays of some tonometer models there is an additional icon that signals high blood pressure.

Tonometer with high pressure indicator

Malfunctions of AND tonometers

Find out about the main problems

Typical malfunctions of the “And” tonometer vary somewhat depending on the type and model, but as a rule, the cause of their occurrence is the human factor. Lack of proper maintenance and care, careless handling and careless operation will eventually lead to failure of the correct operation and functionality of the device and will require the intervention of specialists.

In most cases, the main causes of breakdowns are mechanical damage as a result of improper use, falls and force. Both mechanical and electronic devices, their units and components suffer from this. Loss of sealing of the cuff, damage to the air supply tubes, failure of the pressure gauge, air blower or bulb will require their repair or replacement, and as a rule this does not create difficulties. The most difficult thing is with electronic blood pressure monitors. In addition to mechanical failures, these models are characterized by electronic failures as a result of liquids, especially water, entering the interior of the structure.

Short circuits and burnouts of parts and microcircuits, corrosion of the tracks of the main board lead to at least critical deviations, incorrect display of data or more serious consequences, up to a complete failure to work. In such situations, only timely contact with a specialized specialist and repair of the board or restoration after moisture ingress with thorough washing and drying will be necessary. In any case, self-correction of any malfunction will not bring positive results, since only an experienced engineer is able to identify the cause and extent of damage, and also correct it with minimal losses and costs.

Professional advice

In the Application , please indicate your name, contact phone number and a brief question. A specialist on this topic will contact you within 15 minutes. This engineer will advise and give comprehensive answers to your questions.

Errors during operation

When a tonometer shows different values during paired measurements, it is customary to blame the device, but few people think that the reason lies in improper use.

Common errors when using the device include:

- a cuff that is too tight or not tight enough;

- incorrect position of the cuff;

- incorrect body position;

- frequent measurements.

To eliminate the first three errors, just read the instructions. It describes in detail the procedure, rules for installing the device, body positions and other subtleties of accurate pressure measurements.

Frequent pressure measurements involve a continuous series of measurements to obtain the same readings. The problem is not in the device, but in the artery, which does not have time to return to its normal position after compression. Therefore, with continuous measurements, a discrepancy in the indicators by 30-40 units appears. Between measurements, a time interval of 15 minutes must be observed.

Rules for measuring blood pressure

Characteristics and components of Omron R2

The fully automatic device has a modern design, compact dimensions and a set of many useful functions. The tonometer is designed to measure pulse and blood pressure.

The compact and lightweight Ormon r2 tonometer will accurately measure pressure anywhere

The cuff is anatomical, made using a unique technology. Suitable for wrists with a circumference from 13.5 to 21.5 cm. Manufacturer's warranty - 60 months. The full technical characteristics and equipment of the tonometer can be found in the table: